How Does a FourStroke Engine Work Engineering Discoveries

4 Stroke Engine Theory | Briggs & Stratton Watch on The Briggs & Stratton 4-stroke engine, also referred to as a 4-cycle engine, powers an array of outdoor power equipment, including lawn mowers, generators, lawn tractors and tillers. Our 4-stroke engines lead the world in production and quality.

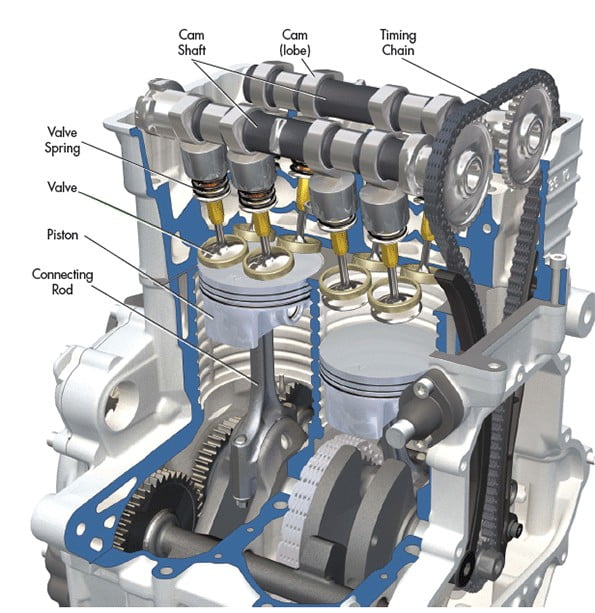

What Are The Components Of 4Stroke Engine? Valves, Cams, Piston etc.

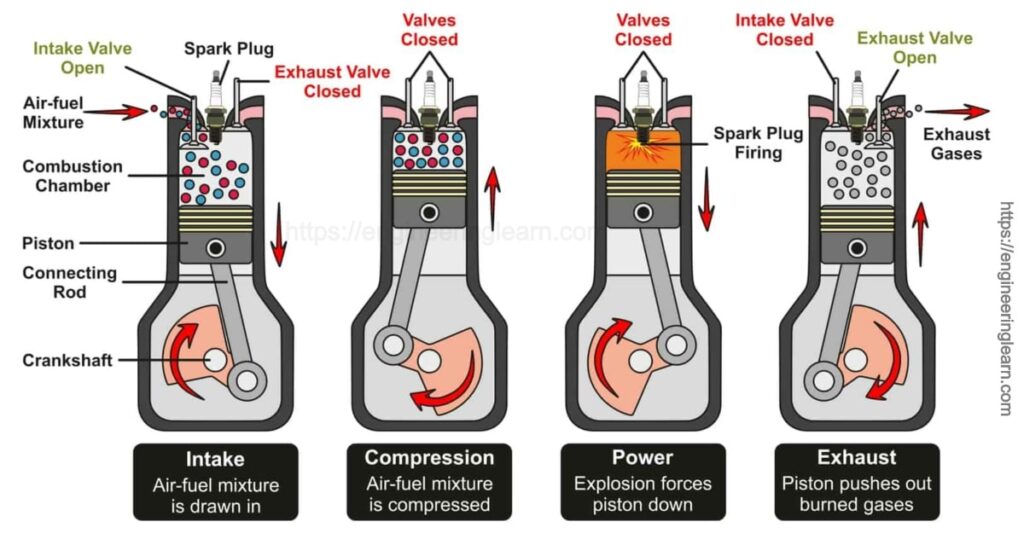

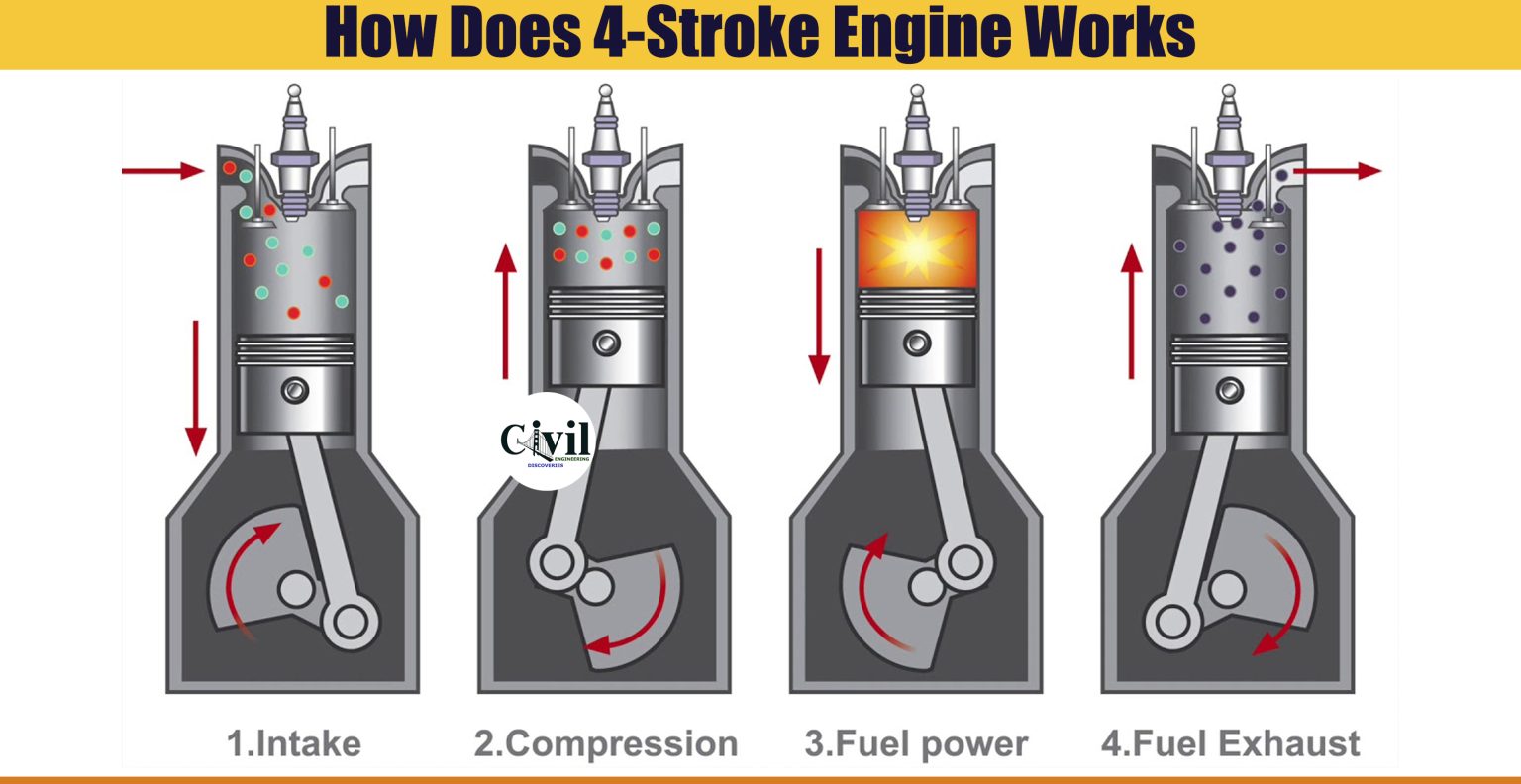

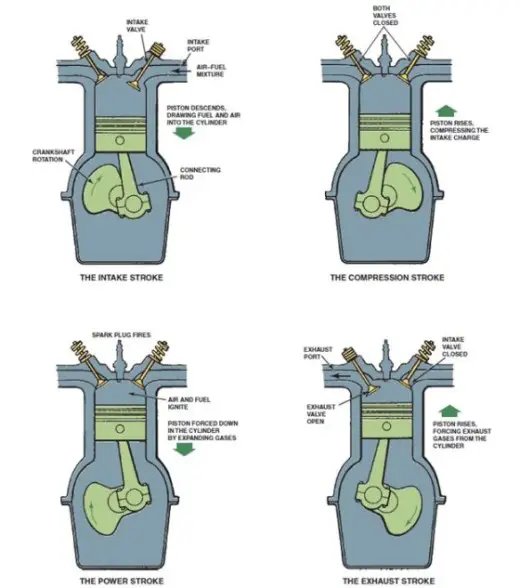

The four stroke engine is probably the most common engine type nowadays. It powers almost all cars and trucks. Speed 10 fps. The four strokes of the cycle are intake, compression, power, and exhaust. Each corresponds to one full stroke of the piston; therefore, the complete cycle requires two revolutions of the crankshaft to complete.

FourStroke Engine Animation, Each Stroke Explained

In compression ignition (CI) engines, burning of fuel occurs due to compression of the fuel to very high pressures. At very high pressures the fuel, i.e. diesel, starts burning automatically without the need of any external flame. The cycle of operation of the CI engine is completed in four-strokes: suction, compression, expansion, and exhaust.

How does a 4 stroke engine work ? MechStuff

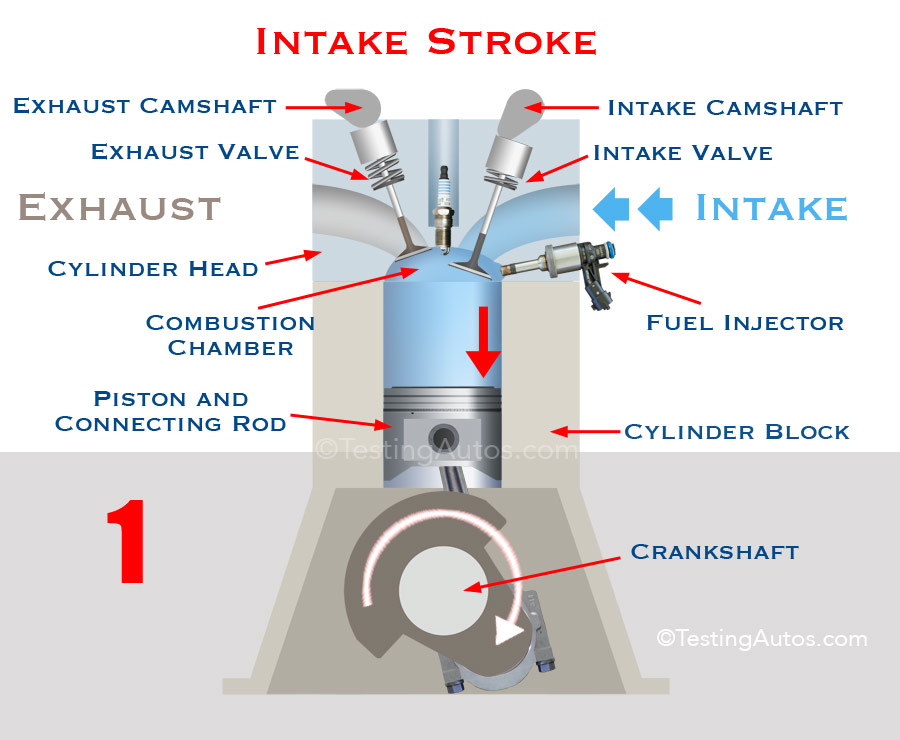

In a four-stroke engine, the four strokes are: 1) Intake Stroke Starting from "Top Dead Center" (TDC), and zero degrees of rotation, the piston moves down the cylinder. As the piston moves it creates a vacuum and the intake valve opens, sucking air into the cylinder.

1. Four stroke diesel engine Download Scientific Diagram

The term, "four-stroke cycle" means that the engine needs to move the piston up or down the bore 4 times to complete all the functions that go into producing power from gasoline. Because the piston is connected to the crank via the connecting rod, each "stroke" takes a half revolution of the crank, or two full revolutions for the four.

4 stroke engine labeled diagram

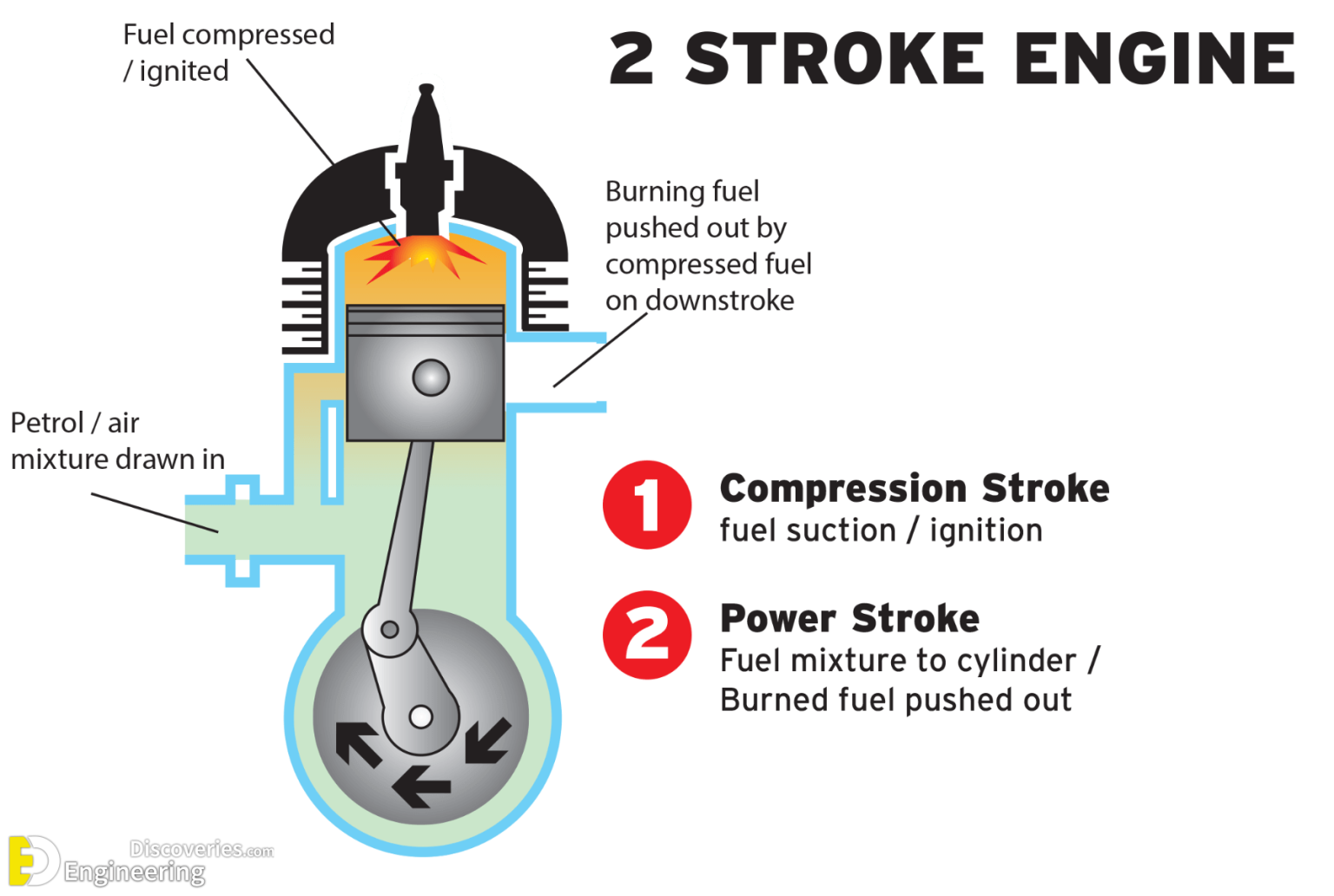

Four Stroke Engine: Principle: We know that stroke is define as maximum movement of piston in any direction inside engine cylinder. For example if a piston moves form bottom dead center to top dead center is known as a stroke. If it returns back to bottom dead center, it is known as 2 stroke.

The Four Stroke Engine Cycle [1] Download Scientific Diagram

Four Stroke Engine Four-Stroke Engine: Learn Definition, Diagram, Parts, Working, and Uses Last updated on Aug 25, 2023 Download as PDF Overview Test Series A four-stroke engine is an internal combustion engine in which the piston rotates the crankshaft four times.

FourStroke Engine Auto Upkeep Academy

The pressure volume diagram (PV diagram) that models the changes the fuel-air mixture undergoes in pressure and volume in a four stroke engine is called the Otto cycle. The changes in these will create heat, and use this heat to move the vehicle or machine (hence why it's a type of heat engine ).

How does 4Stroke Engine Works? and with [Engine Cycle, Diagram

A four-stroke engine is an internal combustion engine that utilises four distinct piston strokes (intake, compression, power, and exhaust) to complete one operating cycle. A complete operation in a four-stroke engine requires two revolutions (720 0) of the crankshaft. In this article, let's study the four-stroke engine. Table of Contents

Mechanical Engineering Marine Engine 4 stroke

1) The process starts with suction stroke, at the time of suction stroke the inlet valve is open and the exhaust valve is in closed condition. The piston moves from TDC to BDC. Piston sucks the fresh charge from the intake manifold. 2) After the suction of fresh charge both valves get closed.

Cross section showing one cylinder of a fourstroke

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed: Intake: Also known as induction or suction.

How Does a FourStroke Engine Work Engineering Discoveries

Four stroke engine working. To give you an idea of how fast this process occurs. A normal bike or scooter engine usually runs at around 4000 to 6000 rpm. That means 4000 to 6000 rotations of the crankshaft per minute. So in one second, the rotation of the crankshaft is. 4000/60 = 66.6 rps 4000 / 60 = 66.6 rps.

four stroke engine Shaik Moin

4 Stroke Combustion 4K SLOW MOTION | 33,000 FPS | Clear Engine Cylinder This videos illustrates the working of 4 stroke engine, with all the four strokes explained and also at the.

How 4 Stroke Engine Works How Does a FourStroke Engine Work

A four-stroke cycle engine is one of the most common type of small engine which is found completing five Strokes in a singly operating cycle which includes intake, compression, ignition, power, and exhaust strokes. 1. Intake Stroke: ( 4 Stroke Engine ) The intakes required whenever there is a need of air-fuel mixture inside the combustion chamber.

4 Stroke Engine Diagram

Category: Science & Tech Also called: Otto cycle or four-cycle engine Key People: four-stroke cycle, principle by which most modern automobile engines function. As illustrated by the figure, while the inlet valve is open, the piston first descends on the intake stroke.

Four Stroke Cycle Engine Operation ASE Certification Training HQ

June 11, 2022 by Himanshu Arora In this article, we will discus about 4 Stroke Engine Working Principle, Diagram. An engine is a device, that converts the energy in a fuel into heat energy and the heat energy into mechanical energy. Before discussing the Four-Stroke engines, we should know the working principle of an IC engine.