The Best Laser Engraving Machine YouTube

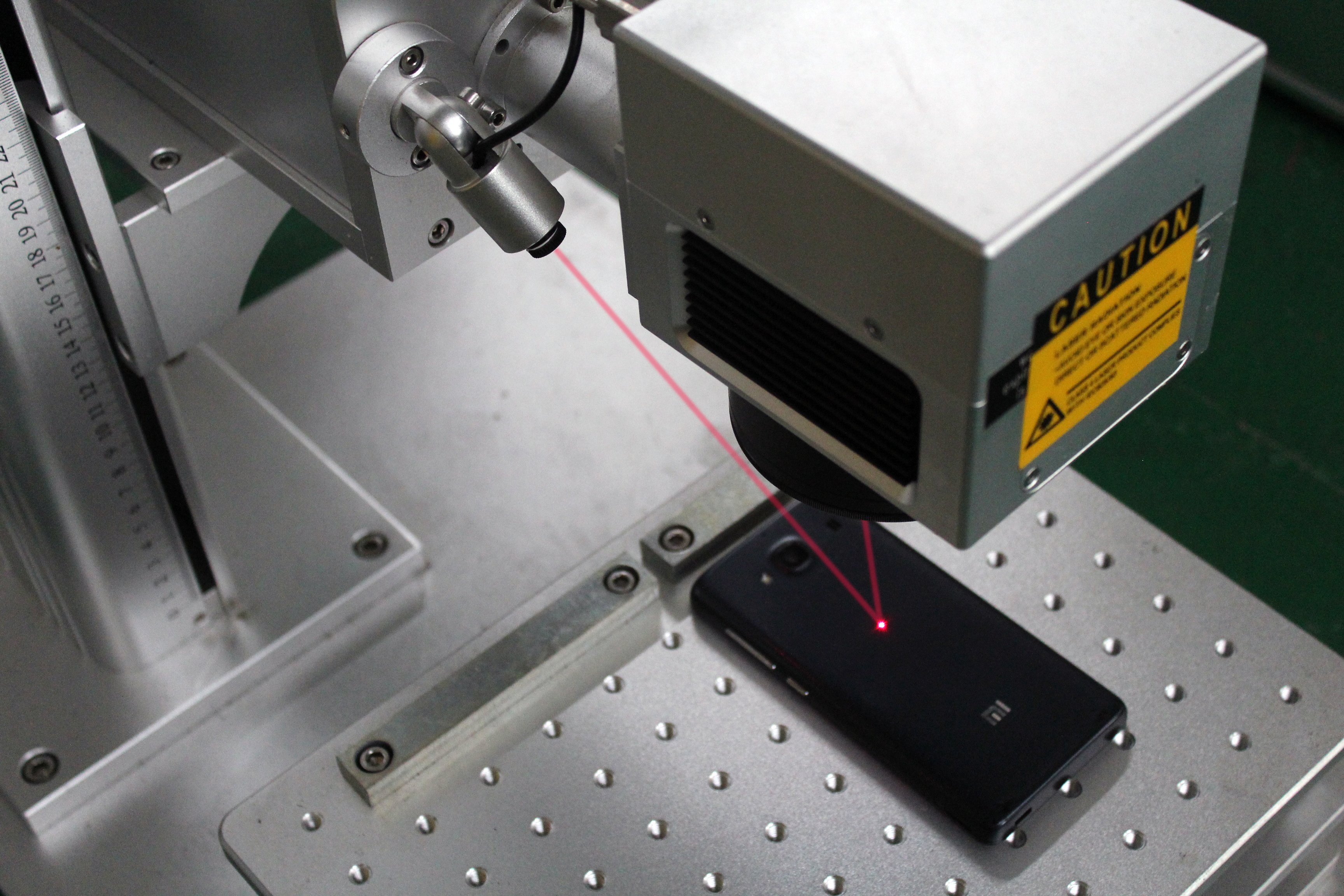

Laser engraving is a process in which the topmost layer of the material is vaporized using a powerful laser beam. The engraving material depends on the type of laser engraver you have. For instance, a CO2 laser can cut softwood, plastic, and bamboo. The Fiber laser is suitable for engraving metals, including engraving on stainless steel.

10 Mindblowing Artists and Makers Using Lasers On Wood AP Lazer

11 min read. Laser engraving is a process used in marking materials with a laser beam. It is used in the automotive, medical, and manufacturing industries while also being extensively used for artistic or aesthetic applications. In most cases, engraving is used because of its ability to produce durable, high-contrast markings.

Laser Engraving vs. Laser Etching What’s the Difference?

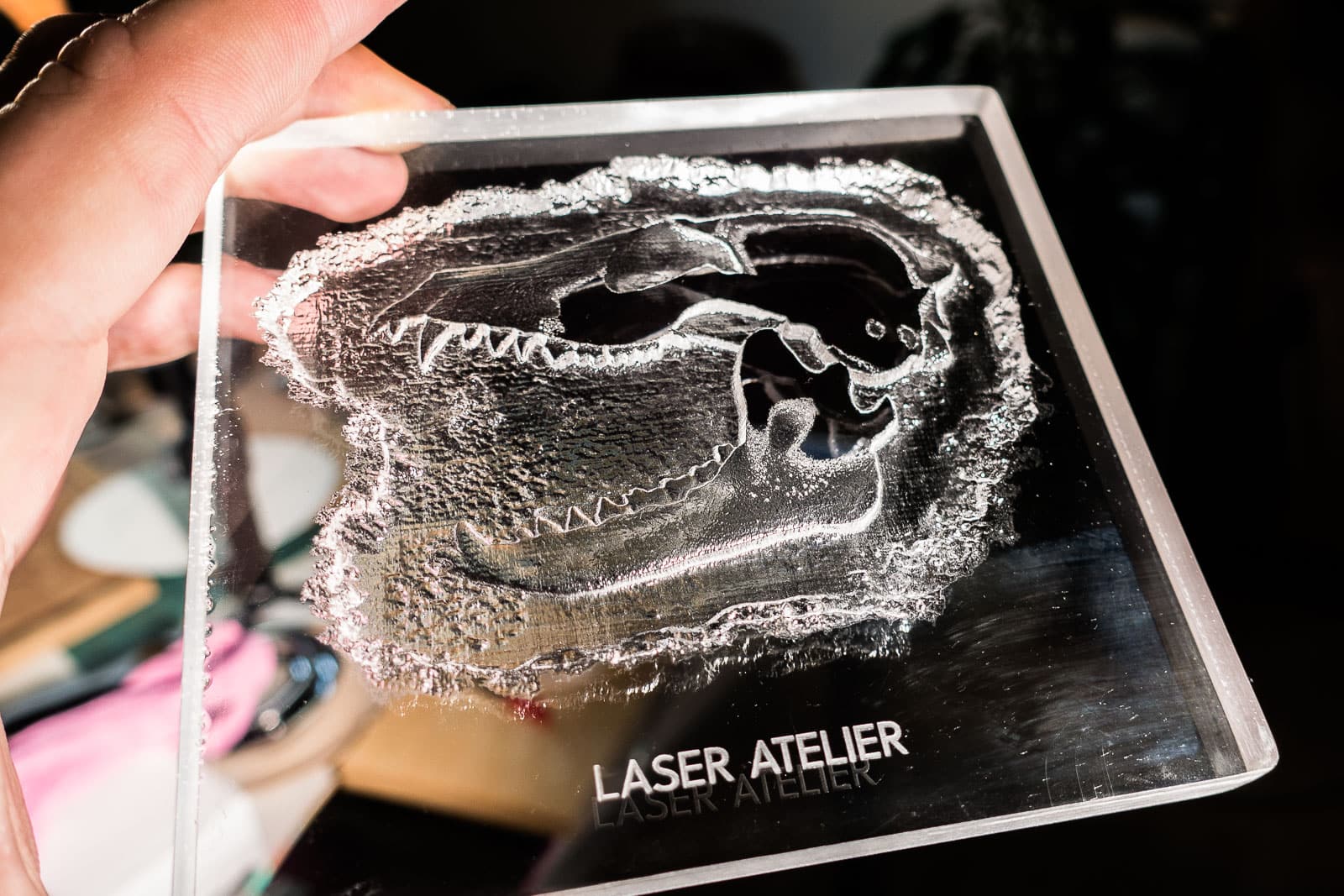

Laser engraving is a meticulous process that harnesses the power of a focused laser beam to carve intricate patterns and designs into a material's surface. Unlike etching, which merely alters the surface, engraving ventures deeper, creating recesses that can be both seen and felt.

Laser engraving, cutting and etching onto wood Positive Marketing

Solaris Laser provides innovative laser coding, marking and engraving solutions to a wide range of businesses and leading brands around the globe. Equipped with many years of industry experience.

21 Fun Laser Engraving Ideas Maker Industry

Advantages of laser etching. Versatility: Laser etching can be used on various materials, including metals, plastics, glass, ceramics, and some organic materials. Precision: It is highly precise and can create fine lines and intricate designs, making it an ideal technique for producing small or detailed marks. Non-contact process: Laser etching is a non-contact process, which means that it.

Laser engraved ideas, Laser engraving, Laser art

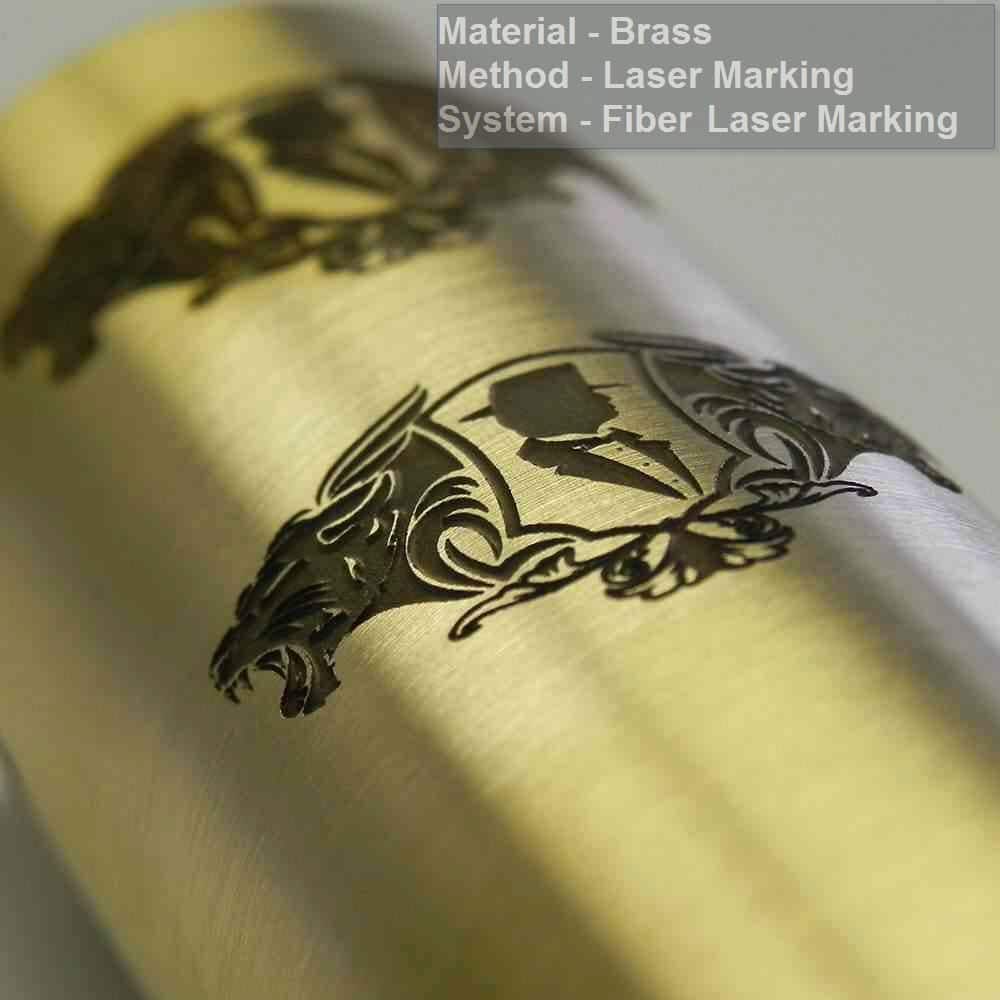

But what sets them apart? While the three techniques may seem similar, there are actually quite a few differences between them. The differences between laser marking, laser engraving, and laser etching largely have to do with what each process does to the marking surface, including how deep the laser goes and how it changes the overall appearance.

How Laser Engraving Technology Is Revolutionizing The Manufacturing

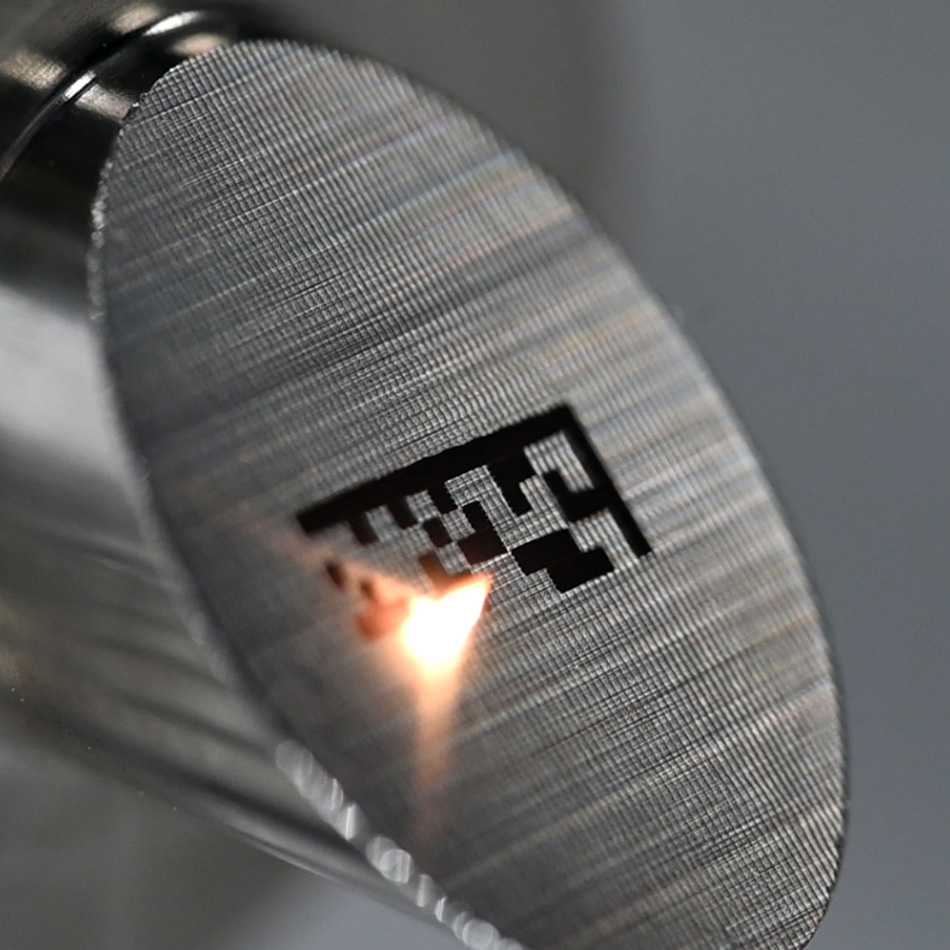

The difference between laser marking, engraving, and etching is the depth at which the laser works during these processes to produce the desired pattern. While laser marking is a surface phenomenon, etching works at around 0.001", whereas laser engraving involves material removal at around 0.001"-0.125".

Laser Marking and Engraving Machines Coherent

Laser engraving involves vaporizing the material, allowing for deep marks on metal, wood, or plastic. On the other hand, laser etching makes the material malleable and causes expansion upon laser contact.

Laser Engraving Services for Industrial, Medical, Aerospace Laser Engraving

The main difference between laser etching and laser engraving is that etching melts the micro surface to create raised marks, whereas engraving removes material to create deep marks. Both processes use high heat to create permanent markings on metal surfaces. Both processes are heavily used for part traceability.

Custom Engraved Wood Custom Engrave Wood Laser Engraving Pros

Laser etching, as the name suggests, uses laser technology to cut through the surface of the metal to create a basic image, or what they often call a lasting image. How laser works are when the laser beam hits the material's surface with a high amount of energy, the metal surface absorbs this energy and converts it into heat.

Laser Engraving Pictures from the

Laser marking techniques: There are three main techniques of laser marking: engraving, etching, and marking. They differ in how they interact with the material and the resulting surface properties. Laser engraving: Laser engraving vaporizes the material and leaves a cavity.

Laser Engraved Photos in Wood Turner Laser Engraving

October 30, 2023 Leo Watts Guides, Laser Engravers, Laser Guides Key Takeaways Laser Marking: A MOPA fiber laser can create different colors on metals and plastics by changing the laser beam properties. Color Filling: You can paint the engraved areas manually with a brush or spray paint.

Plastic laser cutting and engraving Laser Atelier

Best for beginners Best for precision

laser engraving Google Search Engraving art, Laser engraving, Wood

Laser etching is a process that creates marks on parts and products by melting their surface. It is part of the broader category called laser marking which also includes laser engraving and laser annealing. Highly versatile, it can be used with most metals. To produce a raised mark, the laser beam delivers a high amount of energy to a small area.

The Laser Etching Process Hai Tech Lasers

Laser vs Hand Engraving: Laser engraving is faster, more precise, and easier than hand engraving, but has some limitations.; 3D Engraving: Hand engraving can create more depth and 3D effects than laser engraving, which is mostly 2D.; Material Size: Hand engraving can work on any material size, shape, and weight, while laser engraving is restricted by the machine's working area.

Cutting + Engraving Wood with a Laser The Blog

Like laser engraving, etching can be used to produce patterns and traceability features like barcodes, QR codes, and serial numbers. Laser etching can also help manufacturers easily trace a product's manufacturing history. What Is the Most Commonly Used Technique Between Laser Engraving and Etching in Terms of Traceability of Parts?