10 Best Epoxy Resin Fluids For Ultimate Strength

The addition of artemisinin to epoxy resin formulation was reported to impart antimicrobial activity to epoxy resin membranes without damaging mechanical properties . Double bonds in cottonseed oil have been epoxidized and the product was added to DGEBA in different amounts to achieve a bio-based epoxy resin by curing with amine terminated prepolymer.

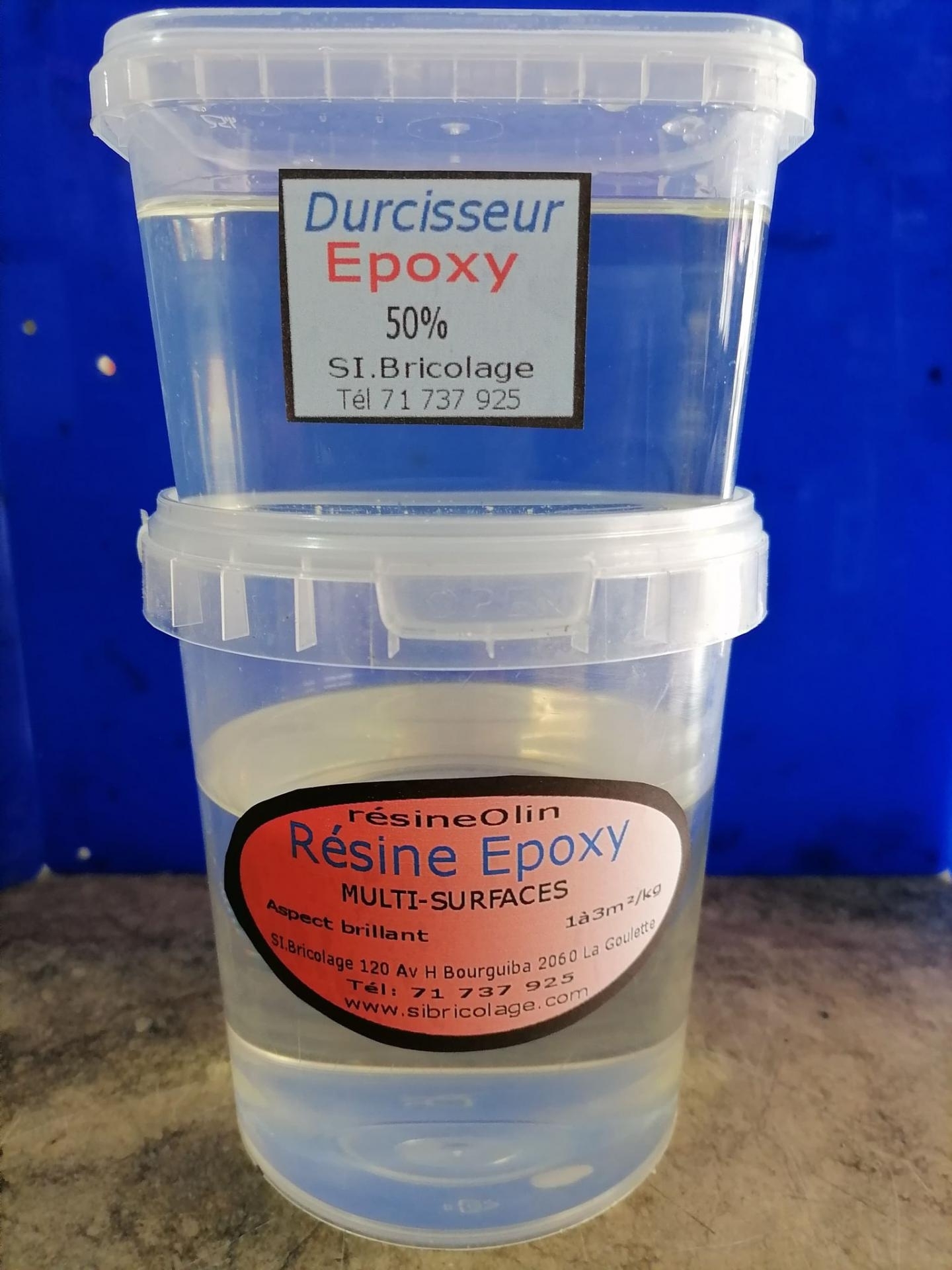

resine epoxy tunisie 38d 1l 71.737.925.

Epoxy resins are reactive intermediates that, before they can be useful products, must be "cured" or cross-linked by polymerization into a three-dimensional infusible network with co-reactants (curing agents).

55 Amazing Epoxy Table Top Ideas You’ll Love To Realize Engineering Discoveries

Epoxy resins are diepoxides and bifunctional alkylating agents, and bifunctional alkylating epoxides are known to be mutagenic 3,4. Mutagens are suspected of having a carcinogenic effect.

Deep Pour Epoxy Resin Specialty Resin Crystal Clear

Indeed, epoxy resin is a core matrix phase for a range of high-performance composites. Epoxies are highly compatible with powder-bound matting, kevlar, and woven roving matt. Carbon fibre is a reinforcement that is very strong and very stiff. In many applications, it is used to reinforce epoxy matrices.

Types and Advantages of Epoxy Curing Agents

Epoxy resins are frequently used in electrical devices, castings, packaging, adhesive, corrosion resistance, and dip coating. In the presence of curing agents, epoxy resins become rigid and infusible. Eco-friendliness and mechanical functionality have emerged as vulcanization properties.

Epoxy Resin 101 How to Choose Like a Pro?

Epoxy resins have been widely used for coatings, electronic materials, adhesives, and matrices for fiber-reinforced composites because of their outstanding mechanical properties, high adhesion strength, good heat resistance, and high electrical resistance.

Epoxy vs Resin Difference between Epoxy and Resin

Epoxy resins are used alone or in combination with glass, carbon, or other reinforcing fibers (aramid) to create all manner of product from boat hulls to electrical components. They are used in the construction trades to anchor bolts and other hardware into concrete walls, ceilings, and floors. They are used as potting compounds, sealants, and.

What is Epoxy Resin? (with pictures)

For resin casting of the second layer, you must first mix new casting resin after the base has cured or dried. Proceed in the same way as with the first mixture. After mixing, you should go over the finished resin with a hot-air dryer to remove any bubbles. Then fill the mold completely with the epoxy resin.

Art Epoxy Resin 11 Ratio Trustic

In studying the anionic polymerization of epoxy resins under the action of imidazoles, along with those previously employed, we chose imidazoles substituted in position 1—1-(n-butyl)imidazole, 1-vinylimidazole, and N,N '-carbonyldiimidazole.The maximum change in the intensity of the bending vibration peak of the epoxy group at 916 cm -1 in the IR spectra of the reaction mixture of the ED.

Ways to Apply and Use Epoxy Resin

Thanks to their high strength, versatility, and excellent adhesion to a variety of surfaces, epoxy resins have gained wide acceptance in diverse applications (coatings, electrical, casting resins, composites, etc.). Explore thermosetting epoxy resins in detail along with their key properties.

INCROYABLES IDÉES DIY AVEC DE LA RÉSINE ÉPOXY 22 CRÉATIONS FACILES AVEC DE LA RÉSINE ÉPOXY

12 EPOXY RESINS 12.1 INTRODUCTION In the plastics industry epoxy resins are classified as thermosetting resins, and they are used in the paint industry as convertible coatings. Epoxy resins are cured and converted to a thermoset state by chemical re action between the resin and a curing agent. Depending on the curing agent this

A Complete Guide to Epoxy Resin RS Korea 한국

Epoxy resins are polymers containing more than two epoxy groups. The epoxy groups in epoxy resin react with a variety of curing agents, such as amines, organic acids, anhydrides, boron.

Safe Alternative To Epoxy Resin

The flexibility of the polymer chains at the interface between the epoxy resin and inorganic particles can be altered by their interaction, hardening the epoxy resin's conformation close to the inorganic particles [62, 63]. EP firmly encases POSS nano-particles and exhibits good dispersibility when the extra POSS nano-particle amount is between 1 and 5%.

Test résine époxy de chez action (étape 1) YouTube

Epoxy resin is a versatile and highly adhesive material widely used in the construction, woodworking, and manufacturing industries. Its exceptional bonding properties, resistance to chemicals and moisture, and ability to withstand moderate temperatures make it a go-to choice for various applications.

Ways to Apply and Use Epoxy Resin

Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called epoxy. [1] The IUPAC name for an epoxide group is an oxirane .

How to Use Epoxy Resin Like a Pro

Epoxy resins are typically cured in the presence of amines or anhydride in a step growth manner, and in some cases Lewis bases such as tertiary amine and imidazoles are also employed.. in an NCO/OH molar ratio of 2.82 under the catalytic action of dibutyltin dioctoate for 2 hours at 70 °C in nitrogen atmosphere. An epoxy resin is then pre.