Dr. Argon Space Demon — Stan Winston School of Character Arts Forums

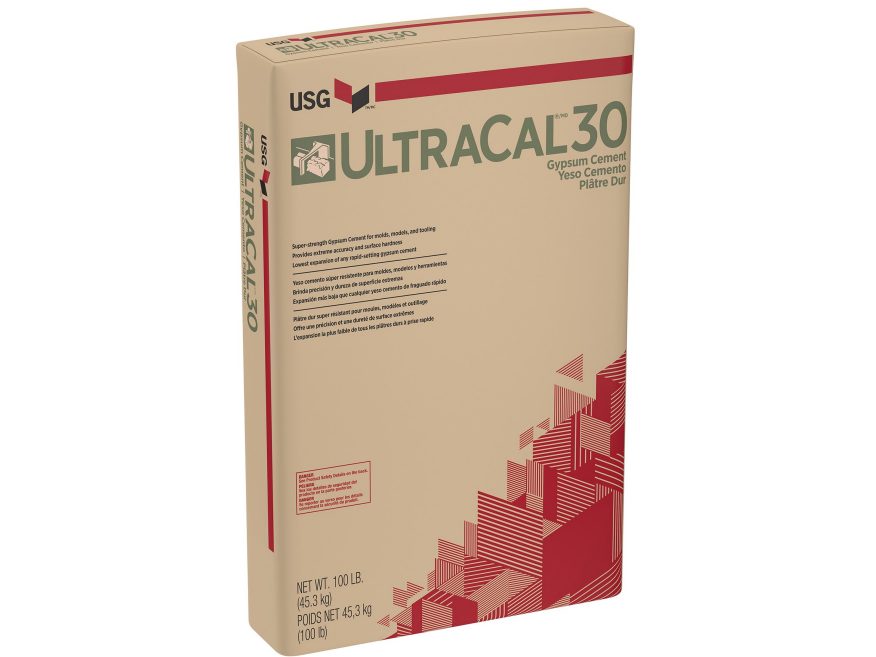

USG Ultracal® Brand 30 Gypsum Cement is designed for the patternmaking industry as the ultimate gypsum cement tooling medium. When extreme accuracy and greater surface hardness are required (as in duplicator models), use USG Ultracal 30 Gypsum Cement. It provides extremely low expansion properties, gradual set and a long period of plasticity.

Browning BAR .3006 caliber rifle for sale.

ULTRACAL 30 is a Super-strength gypsum cement recommended where extreme accuracy and greater surface hardness are required, as in duplicator models. ULTRACAL 30 has the lowest expansion of any rapid-setting gypsum cement available. ULTRACAL 30 was designed to give the pattern making industry the ultimate in a gypsum ce

Ultracal® 30 Gypsum Cement USG

Ideal for splash-casting molds and models for phenolic, polyester and epoxy resins, USG Ultracal 30 Gypsum Cement is water soluble - there is no need for organic solvents for cleanup. USG Ultracal 30 Gypsum Cement is noncombustible. Normal Consistency (lbs. water/100 lbs. product) 33 - 38. Dry Compressive Strength 6,500 psi.

Cal Lightman Dr. Cal Lightman Wallpaper (19841341) Fanpop

Low absorption Ultracal® 30 Gypsum Cement: Is recommended where extreme accuracy and surface hardness are required (i.e. duplicator molds) Provides the lowest expansion of any rapid-setting gypsum cement. Is ideal for splash-casting molds and models for phenolic, polyester and epoxy resins. Sets 25-35 minutes after machine mixing.

SILENCIEUX SL7I ASE ULTRA CAL .30 BORELOCK AVEC FREIN DE BOUCHE

Featuring AVAILABLE IN 5, 25, AND 50LB OPTIONS IN THE DROPDOWN USG Ultracal® Brand 30 Gypsum Cement is designed for the patternmaking industry as theultimate gypsum cement tooling medium. When extreme accuracy and greater surface hardnessare required (as in duplicator models), use USG Ultracal 30 Gypsum Cement. It provides extremelylow expansion properties, gradual set and a long period of.

The 300 Ultra Mag (300 RUM) Your Complete Guide Big Game Hunting Blog

Ultracal 30 has the lowest expansion of any rapid-setting gypsum cement available. Ultracal 30 was designed to give the patternmaking industry the ultimate in a gypsum cement tooling medium. Ultracal 30: Mix Ratio (Parts Water by Weight per 100 Parts of Plaster): 38. Set Time: 25 - 35 minutes.

USG Gypsum Ultracal 30 Plaster 50 Pounds Evans Ceramic Supply

ULTRA CAL 30: Traditional tooling gypsum cement with very low expansion. Formulated for close tolerance tooling where extreme accuracy and surface hardness are required. Used widely in the SPFX industry to make hard, super strong precise molds. Ideal for Foam Latex molds, where durability and detail reproduction are a concern.

Viên Canxi NANO NZULTRA CAL NHÀ THUỐC VIETCARE84

USG ULTRACAL 30 is a low-absorption gypsum cement for case molds. Specially made for close-tolerance tooling - provides the greatest hardness, accuracy and freedom from efflorescence of any gypsum cement on the market. This pottery cement is recommended where extreme accuracy and greater surface hardness are required, as in duplicator models.

Ultracal 30, 50 lb

Primarily used as a u001amass-casting materialu001a where the mold is poured from solid gypsum, Ultracal 30 is the most popular gypsum used in tooling applications because of its good surface hardness, high compressive strength and low expansion. This material offers a slightly higher surface hardness and compressive strength then Hydrocal B-11.

Ultra Cal 30 and White Hydrocal (Gypsum Cement) 50 lbs.

It was designed to give the pattern making industry the ultimate in a gypsum cement tooling medium. MIX RATIO: The manufacturers recommended mix-ratio of Ultra Cal 30 is (38 parts water to 100 parts) Ultra Cal 30 by weight. The average setup time is 25-35 minutes when manually mixed. Please note that parts can be in grams, ounces or pounds etc.

Ultra Cal/Mag Formula 120 caps Shop The Care Group LLC

Description. A superior tooling gypsum cement features exceptional strength and hardness. Ultracal 30 should be fully dispersed in the water prior to mixing. 50 lbs. $0.35 per pound. For larger quantities, click here for a quote. Weight. 50 lbs. Dimensions. 25 × 17 × 8 in.

USG Ultracal® 30 Gypsum Cement 47.5 lbs. Plaster

A low-absorption gypsum cement for case molds. Specially made for close tolerance tooling; provides excellent hardness, accuracy and freedom from efflorescence. Mix Ratio: 33-38 lbs. water/100lbs. Ultracal. Set Time: 18-30 min. Selection of the water-to-plaster ratio must be based on the particular requirements of the set plaster.

Dr. Argon Space Demon — Stan Winston School of Character Arts Forums

Harder and stronger than HYDROCAL A-11 and HYDROCAL B-11 cements, UltraCal® 30 cement has the lowest expansion of any rapid-setting gypsum cement available. Has a gradual set and long period of plasticity. Ideal for splash-casting molds and models for phenolic, polyester and epoxy resins. It was designed to give the patternmaking industry the.

Ultracal 30 Gypsum Cement Gypsum Plaster Dalchem

Low absorption Ultracal® 30 Gypsum Cement:Is recommended where extreme accuracy and surface hardness are required (i.e. duplicator molds)Provides the lowest expansion of any rapid-setting gypsum cementIs ideal for splash-casting molds and models for phenolic, polyester and epoxy resinsSets 25-35 minutes after machine mixingRequires 38 parts.

Ultracal 30 Plaster Stage and Screen FX

ULTRACAL 30 Gypsum Cement, Plaster New York, Gypsum NY, usgplaster.com. 330 Hendrickson Ave., Lynbrook, NY 11563 • Tel.: 718-599-1799 • Fax: 718-963-9465. USG ULTRACAL ® 30 Gypsum Cement. Super-strength gypsum cement recommended where extreme accuracy and greater surface hardness are required, as in duplicator models. Harder and stronger.

BPS Balıkesir Explosives Industry

Ideal for splash-casting molds and models for phenolic, polyester and epoxy resins. It was designed to give the pattern making industry the ultimate in a gypsum cement tooling medium. MIX RATIO: The manufacture recommended mix-ratio of Ultra Cal 30 is (38 parts water to 100 parts) Ultra Cal 30 by weight.